Galvo Scanner: Precision Laser Scanning for Industrial Applications

Galvo Scanner: Precision Laser Scanning for Industrial Applications

Blog Article

A Comprehensive Overview to Different Sorts Of Galvo Scanners and Their Applications

Galvo scanners, known for their rate and precision, are integral to an array of sectors from making to medical technology. This overview will discover the different types, such as dual-axis and single-axis scanners, each customized for particular jobs and intricacies. As we navigate via the distinct features and crucial considerations, you'll acquire understanding into just how these scanners improve efficiency and accuracy in their corresponding applications. The trip to choosing the optimum galvo scanner for your operational demands begins with recognizing these nuances. Exactly how do these different types provide to diverse industrial needs?

Basic Introduction of Galvo Scanners

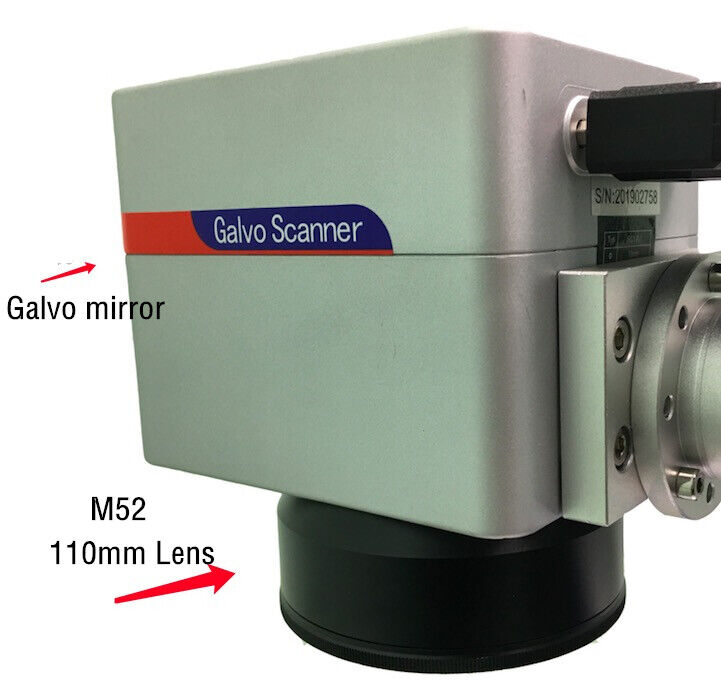

Galvo scanners, brief for galvanometer scanners, are accuracy gadgets used to route laser beam of lights accurately and quickly throughout a marked area. These gadgets play an essential duty in various sectors, consisting of medical, manufacturing, and research study, by promoting high-speed and high-precision laser applications. Essentially, a galvo scanner contains a tiny, lightweight mirror connected to a galvanometer, which is an electromechanical tool that gauges electrical current by deflection of a needle. In this context, the galvanometer's deflection mechanism moves the mirror to steer the laser beam of light.

The core principle behind galvo scanners is the rapid and accurate control of the mirror's angle, which consequently alters the direction of the laser beam. This is achieved through a closed-loop responses system that ensures the mirror's position is continuously monitored and readjusted for precision. The comments system makes up position sensing units, control electronic devices, and high-performance electric motors, providing phenomenal responsiveness and accuracy.

Galvo scanners master applications requiring recurring and detailed laser movements, such as laser inscription, reducing, and medical imaging. Their ability to run at high rates without sacrificing accuracy makes them crucial in situations demanding both effectiveness and accuracy.

Kinds Of Galvo Scanners

When exploring the kinds of galvo scanners, it's essential to recognize that variants are mostly based on their layout, application demands, and performance requirements. Typically, galvo scanners can be categorized right into single-axis and dual-axis versions. Single-axis scanners are designed to relocate a beam in one direction, either horizontally or vertically. These are usually utilized in applications such as barcode scanning and laser engraving, where precision in a single measurement is vital.

Dual-axis galvo scanners, on the other hand, supply two-dimensional control of the light course. This makes them important in even more complex applications like laser light programs, 3D printing, and clinical imaging. Dual-axis models are commonly outfitted with 2 mirrors and equivalent galvanometers, enabling vibrant control over both X and Y works with.

Trick Functions to Take Into Consideration

A number of vital functions need to be carefully reviewed when choosing a galvo scanner for your details application. Speed is an essential characteristic, as it establishes the scanner's ability to deal with high-frequency jobs successfully. The rate is typically determined in regards to feedback time and the maximum number of points per 2nd the scanner can resolve.

Another crucial attribute is the scanner's variety of activity, which indicates the optimum angular deviation it can attain. A wider array provides higher adaptability but might call for more advanced control systems. Thermal security also requires focus, as temperature changes can impact efficiency; thus, go with scanners with durable thermal monitoring systems.

Industry-Specific Applications

In various industries, galvo scanners play a crucial role by my latest blog post enhancing precision and effectiveness in specialized applications. In the clinical field, galvo scanners are indispensable to laser surgeries and ophthalmic procedures, where high-speed, precise beam of light positioning is critical. These devices enable minimally invasive surgical treatments by exactly targeting cells, hence reducing recovery times and enhancing client results.

In production, galvo scanners are vital for laser inscription, reducing, and welding. Their capacity to promptly and properly straight laser beam of lights guarantees top notch surfaces and complex outlining, which is crucial for the manufacturing of complicated elements in automobile, aerospace, and electronics sectors. The fabric sector additionally takes advantage of galvo scanners in material cutting and engraving, providing both speed and accuracy in handling diverse products.

Choosing the Right Galvo Scanner

Selecting the appropriate galvo scanner is a vital decision that rests on a number of essential aspects, consisting of application demands, performance specs, and budget plan restrictions. Plainly you could check here specify the application needs. Whether the scanner is meant for laser inscription, medical imaging, or 3D printing, each application demands specific efficiency features such as resolution, speed, and accuracy.

2nd, take into consideration the performance specifications. Criteria like check angle, action time, and thermal security are important (galvo scanner). A high-speed galvo scanner with a wide check angle is optimal for large-area noting, while applications needing great detail may prioritize high resolution and accuracy

Third, account for budget plan restraints. High-performance galvo scanners come with a considerable financial investment, yet their lasting advantages can outweigh initial costs. Assess the overall expense of possession, consisting of upkeep, to ensure the chosen scanner offers value over its life expectancy.

Final Thought

Comprehending the diverse types of galvo scanners and their special capacities is critical for optimizing performance throughout numerous industries. Single-axis and dual-axis versions provide to various functional intricacies, while high-speed and high-precision versions attend to specific demands in manufacturing, fabrics, clinical areas, and 3D printing. Cautious choice based on the distinct features and application requirements of each kind of galvo scanner makes certain boosted effectiveness and accuracy, thereby significantly improving overall functional end results.

Galvo scanners, short for galvanometer scanners, are precision tools utilized to guide laser beams properly and quickly across a marked location.When discovering the types of galvo scanners, it's essential to Going Here recognize that variants are mainly based on their layout, application demands, and performance requirements. Each kind of galvo scanner is thus uniquely customized to satisfy specific functional needs, making certain ideal performance throughout various applications.

The accuracy of a galvo scanner directly influences the high quality of the output, making it crucial to think about the scanner's ability to preserve high-resolution efficiency (galvo scanner). Cautious option based on the distinct attributes and application demands of each kind of galvo scanner makes sure enhanced effectiveness and precision, thus significantly enhancing total operational results

Report this page